About

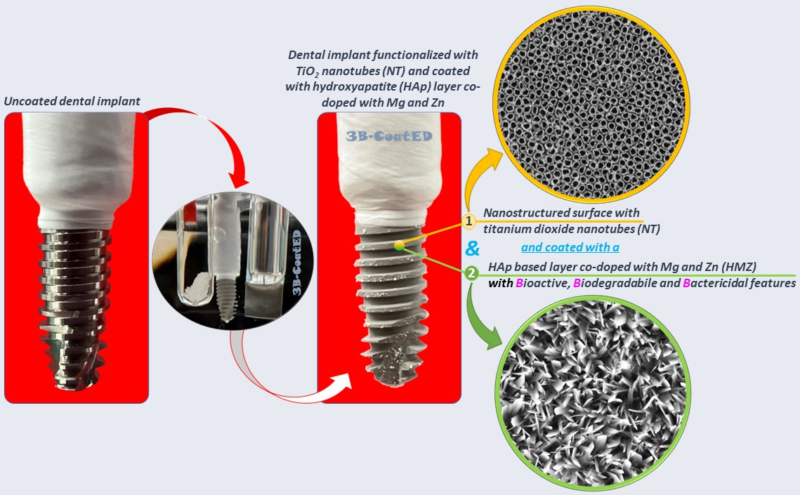

During the years, the use of orthopedic and dental implants has grown dramatically, due to the increasement in geriatric population. Unfortunately, a large number of patients ends up with rejection of the implant due to infection or low osseointegration that ultimately leads to revision surgery. The nowadays trends are directed towards surface modification - from passive to active - involving the usage of bioactive coatings with balanced osseointegration ability, controlled degradation and antibacterial features to enhance bone tissue growth, thereby assuring early mechanical bone-fixation and increased the service lifetime of the implants. The aim of to the present proposal is to develop a novel techniques for bioactivation of pure Ti in two stages using electrochemical methods as follows: 1st stage - anodic oxidation of the Ti in order to obtain a nanostructured surface consisting in TiO2-NT and 2nd stage - electrochemically assisted deposition of nanostructured HAp undoped and doped with Mg or/and Zn with enhance bioactivity properties and bactericide effect. The characterization will be jointly carried out in terms of morphology, elemental and phase composition, chemical bonding, adhesion, wettability, in vitro degradation, bioactivity and electrochemical investigations which will be achieved in biological simulated media (SBF, PBS, DMEM and AS) at 37 °C, mimicking the human environment. In order to evaluate the biocompatibility of the obtained surfaces in vitro cytotoxicity, cells viability and antibacterial activity tests will be performed. Through the proposed experimental research strategy, enhanced multifunctional surfaces that can effectively balance osseointegration with bactericide features that can be maintained on a long-term can be developed, this being critical for the viability of the implant functionalization technologies.

Project aim:

The following objectives will be reached:

• development of a new technique for bioactivation of Ti by using a duplex electrochemical treatment in 2 stages: 1) development of a nanostructured surface of NT-TiO2 through anodic oxidation and 2) development of a new generation of bioactive, biodegradable and bactericide coatings consisting in undoped and M doped ( where, M = Mg, Zn, Mg + Zn) HAp based films through electrochemical techniques;

• highlighting and correlating the properties/characteristics of the developed surfaces;

• development of one experimental model.

Team project:

Diana Maria Vranceanu

Cosmin Mihai Cotrut

Elena Ungureanu

Ionut Cornel Ionescu

Gabriela Juravlea

Results and application:

The main objective of the 3B-CoatED project is to improve the quality and lifetime of the implantable medical devices manufactured from titanium and/or titanium alloys by modifying their surfaces through electrochemical methods as follows:

- surface modification at nanometric level (nanostructuring), providing a morphology/structure that consists in titanium dioxide nanotubes,

- coating the nanostructured surface, previously developed, with a layer of hydroxyapatite doped with Mg and Zn.

The electrochemical techniques selected and developed within the framework of the 3B-CoatED project can ensure a successful surface modification treatment, of the implantable medical devices with complex geometries, such as the one of a dental implant.

The nanostructured surface, and subsequently coated with a layer of hydroxyapatite (HAp - the main mineral component of the bone) will stimulate the biological processes, offering a faster integration rate and a firm anchoring through the growth of bone around the implantable medical device. Addition of small amounts of magnesium (Mg) in the HAp layer, can intensify this process known as osseointegration, leading so to a much faster integration of the implant within the bone structure, that can reduce the time necessary for the patients to be able to use/exploit the implantable medical device to its maximum capacity.

To prevent the possible local reactions associated with the implant that can appear after the surgical procedure, which untreated can lead to failure and even the removal of the implant, small amounts of zinc (Zn), which is known for its antibacterial role and its importance in the bone remodeling process, can also be added within the HAp layer, in order to offer bactericidal properties.

In this manner, the newly developed hard bone tissue that will form around the implant through the help of the hydroxyapatite layer doped with Mg and Zn will ensure a better fixation and stability of the implant due to the nanostructured surface, increasing so its lifetime and offering a longer period until an eventual replacement (surgical revision).

Thus, in terms of patient satisfaction and benefits, these types of solutions which can reduce the osteointegration time and prevent the implant associated infections, can positively impact the patient’s day-to-day activities, such as their social life and/or job-related ones.